BRIL-FOAM

- Home

- BRIL-FOAM

BRiLFOAM FOR ROTATIONAL MOULDING

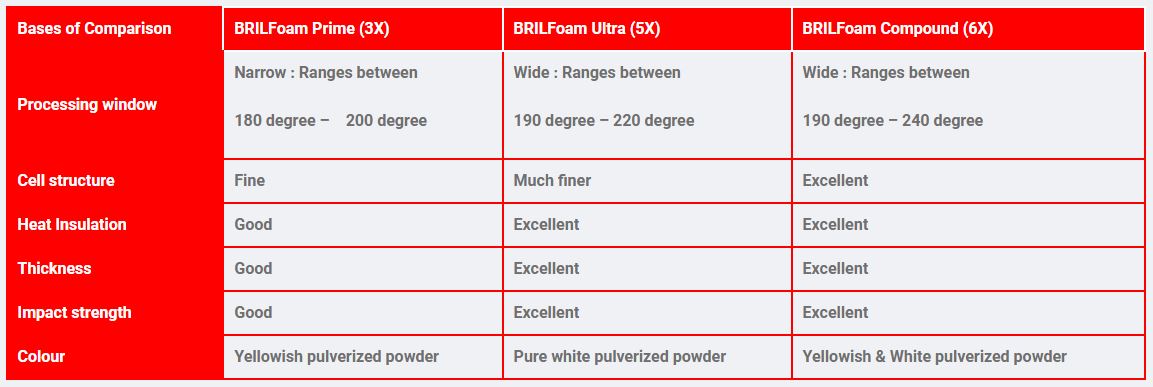

Enhancing Polymer Structures through Innovative Foaming Agents.In the realm of rotational moulding, the introduction of foaming agents plays a pivotal role in shaping the final product. These additives release gas either through chemical reactions or thermal decomposition, resulting in the formation of a distinct cell structure within the polymer matrix. BRiLFOAM stands at the forefront of this technology, having developed foaming agent powders specifically based on the Exothermic blowing agent category.

Enhancing Polymer Structures through Innovative Foaming Agents.In the realm of rotational moulding, the introduction of foaming agents plays a pivotal role in shaping the final product. These additives release gas either through chemical reactions or thermal decomposition, resulting in the formation of a distinct cell structure within the polymer matrix. BRiLFOAM stands at the forefront of this technology, having developed foaming agent powders specifically based on the Exothermic blowing agent category.

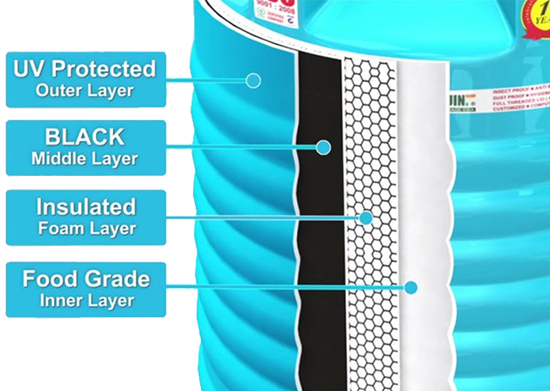

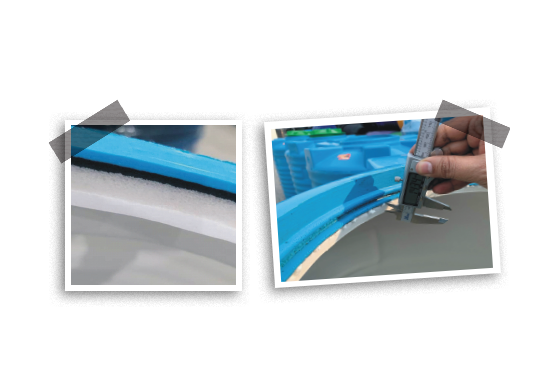

Our foaming agent, seamlessly dispersed in polyolefinic resin alongside specialty chemicals, contributes to the creation of a finely textured cell structure in Rotomoulded LLDPE tanks. Notably, being in powder form, our foaming agent eliminates the need for additional pulverization costs that would otherwise burden the customer.

Applications:

- Rotomoulded LLDPE tanks

- Underground Tanks

- Ice Boxes

- Pallets

- Fish Boxes

- Marine equipment (kayaks, surfboards, floaters, boats)

- Toys

- Vehicle bodies

- Materials handling

- Infrastructure (road barriers, temporary housing, cabins)

Advantages:

- Reduced Weight-to-Strength Ratio

- Enhanced Rigidity at a Lower Price Point

- Exceptional Thermal Insulation Properties

- Outstanding Impact Strength between Layers

- Ready-to-Use Foam Powder

- Uniform Structure throughout the Product

- Ease of Processing

- Finer Cell Structure in Comparison to Conventional Foaming Agents

- Minimal Skill and Technical Expertise Required

Contact

Plot No.21, De-Gaul Avenue, Durgapur-713 206, WB, India.

Plot No.91, G.I.D.C. Estate, Amreli-365 601, Gujarat, India.